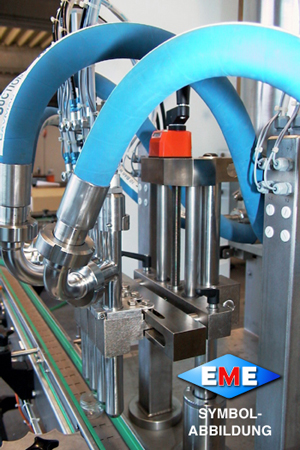

EME Labelling Station |

|

|

|

ApplicationApplication of a body-label to containers of the most varied shapes (cylindrical, flat, oval, rectangular etc.) CapacityNominal capacity according to VDI 2651 (effective capacity):2.500/hour, non-transitionally adjustable (if additional) devices are installed or if the containers have a low stability-grade, then the capacity might be reduced, if an accumulation device is installed, the speed is reduced to 2.000/hour Basic construction

Bottle transport

Labelling station

LubricationThe gearwheels in the socket of the machine are lubricated automatically by means of a long-life grease cartridge DriveMain drive via a completely closed 0,75 KW three-phase A: C: motor, standard 220/380 volts, 50 cycles, speed regulation by means of a hand wheel |

|

| home > manufacturing programme > special machines > labelling station | ||

|

© 2005: EME Engler, Carl-Zeiss-Straße 10, D-74078 Heilbronn-Kirchhausen

|

||